Overview of Bearings in Humanoid Robots

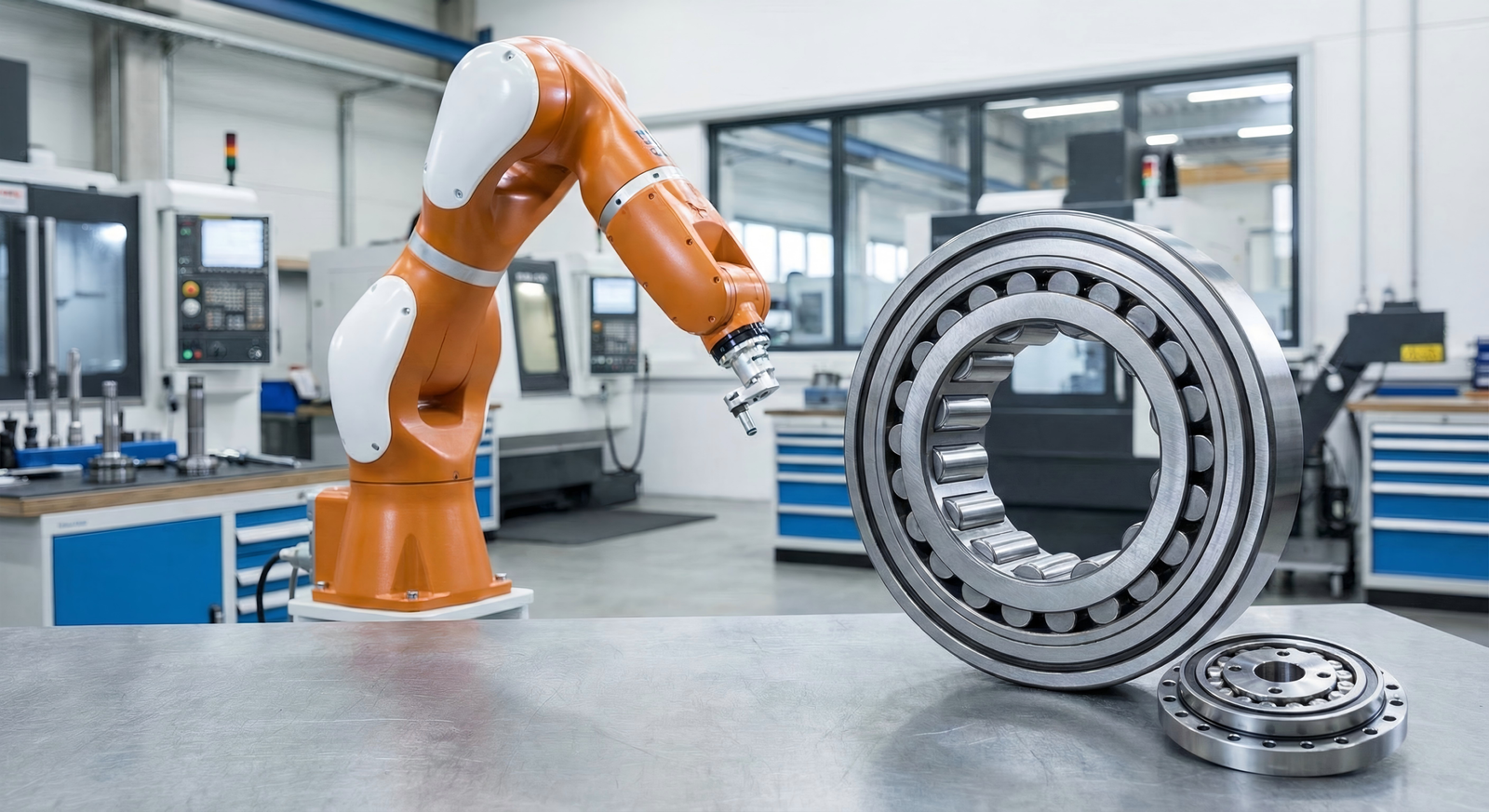

Bearings are indispensable components in the joint modules of humanoid robots. They primarily undertake the roles of support, guiding rotation, and reducing friction, enabling the robot’s joints to move more smoothly while reducing energy loss. Their performance directly affects the precision, efficiency, and lifespan of the robot joints. Robot bearings include various design types, each with its own advantages. The selection depends on the specific application’s requirements for load capacity, speed, precision, and rigidity.

In humanoid robots, bearings are mainly distributed in reducers and joint connections. Linear joints (lead screws) mainly use four-point contact bearings and deep groove ball bearings, while rotary joints typically use angular contact bearings and crossed roller bearings.

The bearings required for reducers are more complex and can be classified according to the type of reducer:

- (1) Harmonic Reducer: Uses one Crossed Roller Bearing (Rigid Wheel) and one Flexible Bearing.

- (2) Planetary Reducer: Uses Ball Bearings at the input and output ends, and requires Needle Roller Bearings to match the planetary gears.

- (3) RV Reducer: Uses 3*2 Needle Roller Bearings, 3*2 Tapered Roller Bearings, and 2 Angular Contact Bearings.

△ Schematic diagram of Harmonic Reducer structure

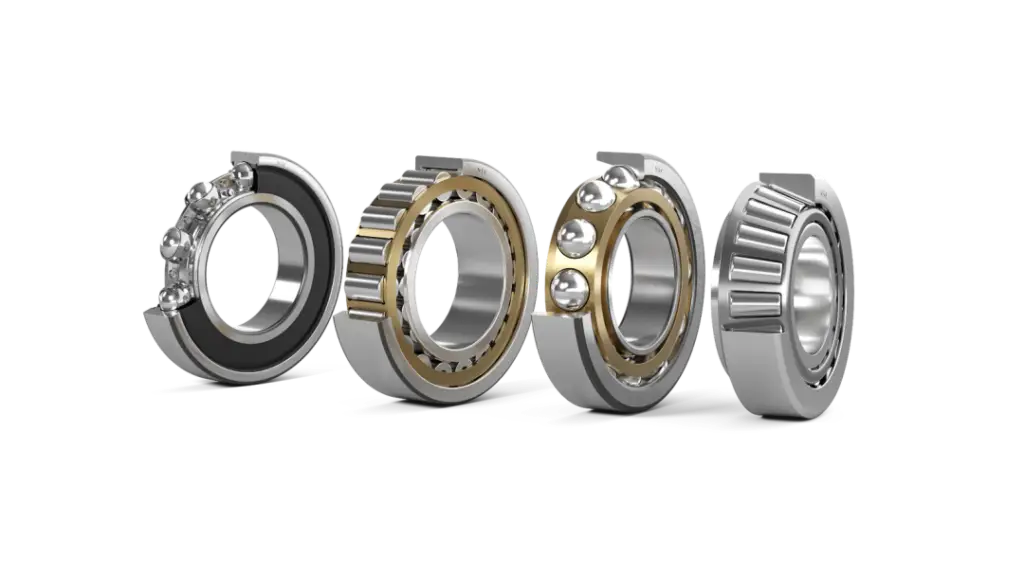

Introduction to Various Bearing Types

Introduction to Bearing Types

1. Crossed Roller Bearings

Crossed Roller Bearings are compact bearings with rollers arranged orthogonally between the inner and outer rings. They combine three major advantages: high load capacity, high precision, and compact design. They can withstand bidirectional axial loads, radial loads, overturning moments, and combined loads. As output bearings for rotary actuators, they are renowned for low friction torque, minimal clearance, high durability precision, and unique load capacity.

△ Schematic diagram of Crossed Roller Bearing (Source: PMI)

2. Flexible Bearings

Flexible Bearings transmit motion and power by utilizing the controllable elastic deformation of flexible elements. Currently, they are mainly used in harmonic reducers, hence also known as harmonic reducer bearings. As the core component of the wave generator, the flexible bearing has thin inner and outer ring walls. It can deform periodically under the action of the cam, driving the flexspline to produce elastic deformation, achieving high reduction ratios and zero-backlash transmission. It features high precision, high load capacity, high torque, and small volume.

△ Flexible Bearing (Source: Hongyuan Bearing)

3. Angular Contact Ball Bearings

Angular Contact Ball Bearings feature raceways on the inner and outer rings that are displaced relative to each other in the direction of the bearing axis. They are suitable for bearing combined loads (radial and axial loads acting together). Their axial load capacity increases as the contact angle increases.

Angular contact ball bearings can be divided into single-row angular contact ball bearings, double-row angular contact ball bearings, and four-point contact ball bearings.

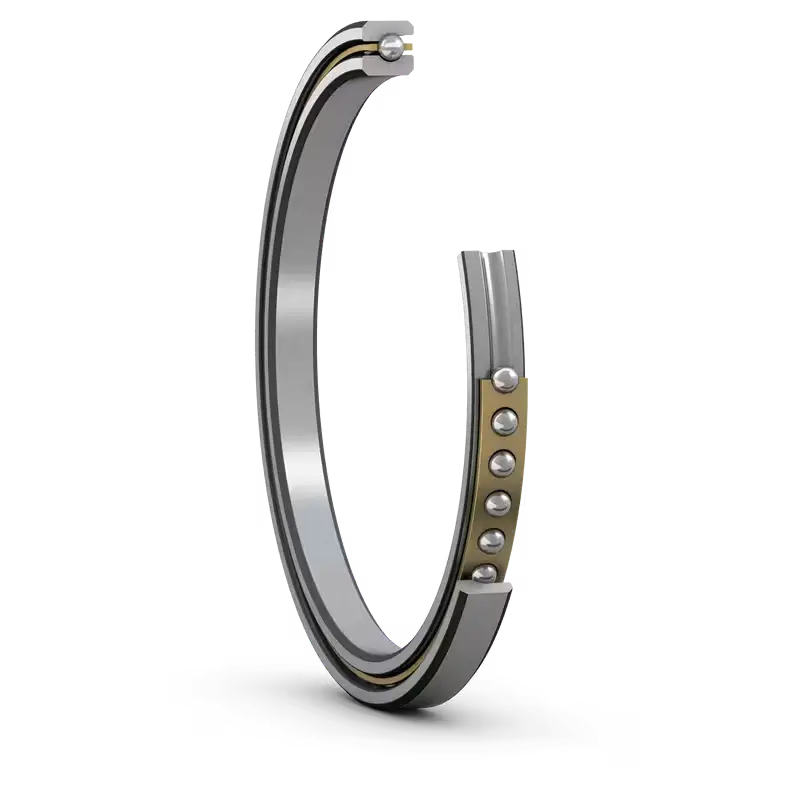

4. Four-Point Contact Bearings

Four-Point Contact Bearings are radial single-row angular contact ball bearings. Their raceways are designed to support axial loads acting in two directions. They are a solution that combines versatility, compactness, and cost-effectiveness. Some models use a split inner or outer ring design to increase the contact angle for withstanding higher axial forces and moment loads. They are commonly used as input bearings for rotary actuators.

The structure of a four-point contact bearing includes a solid outer ring, a split inner ring, and a ball and cage assembly with a brass or polyamide cage.

△ Four-point Contact Ball Bearing (Source: SKF)

5. Needle Roller Bearings (Cylindrical Roller Bearings)

Needle Roller Bearings (Cylindrical Roller Bearings) are bearings where cylindrical rollers make line contact with the raceways. They have a high load capacity and mainly support radial loads. Friction between the rolling elements and the raceway ribs is low, making them suitable for high-speed rotation. Additionally, since the inner and outer rings can be separated, they are easy to install and dismantle.

Cylindrical roller bearings achieve heavy load bearing with a compact structure, effectively suppressing actuator oscillation and improving controllability and rigidity. In addition to high durability and uniform contact stress, they also feature low noise and vibration characteristics, making them ideal for rotary actuators and linkage assemblies.

6. Deep Groove Ball Bearings

Deep Groove Ball Bearings have deep arc-shaped raceways on the inner and outer rings. They can withstand radial loads and bidirectional axial loads, and are suitable for high-speed rotation. They are one of the most widely used bearings. Known for their simple structure, reliable operation, and ease of maintenance, they feature high precision, low clearance torque, and high load capacity. Seals can be added according to requirements.

7. Tapered Roller Bearings

Tapered Roller Bearings are separable bearings. Both the inner and outer rings have tapered raceways, and the rollers are conical. The rollers and raceways are in line contact. They can withstand heavy combined radial and axial loads, as well as pure axial loads. The larger the contact angle, the higher the axial load capacity. Tapered roller bearings come in different structural types, such as single-row, double-row, and four-row tapered roller bearings.

△ Tapered Roller Bearing (Source: SKF)

Market Overview

As core basic components of equipment manufacturing, bearings are widely used in many fields and have broad market prospects. China has a developed basic industry, and the bearing industry has a complete industrial chain. The upstream covers metal materials like bearing steel and stainless steel, non-metal materials like modified plastics, and components like bearing rings. The midstream manufacturing link produces bearings for automobiles, construction machinery, wind power, etc. The downstream is widely applied in automobiles, robots, home appliances, and many other fields, with stable market demand. Among them, the processing precision of robot bearings is finer than that of automotive and machine tool bearings. Currently, RV and harmonic reducer bearings have achieved domestic mass production.

From a global market perspective, overseas leaders such as SKF and Schaeffler still dominate. According to the SKF 2024 Annual Report, the top six global rolling bearing manufacturers hold a combined market share of 55%. Meanwhile, Chinese bearing enterprises are catching up quickly through continuous technological innovation and market expansion, promoting the process of domestic substitution.

Supplier Introduction

Below is an introduction to relevant suppliers:

Domestic Enterprises

1. Zhongshan TCB Bearing Manufacturing Co., Ltd. (TCB)

Website: http://www.tcbbearing.com/

Company Profile: Established in 1968, TCB Bearing Manufacturing Co., Ltd. is a specialized bearing manufacturer based in Zhongshan, Guangdong. Formerly the state-owned Zhongshan Bearing General Factory, the company has over 50 years of experience in R&D and manufacturing. TCB is a synonym for China bearings of the highest quality and precision. The company is known for its high-quality rolling bearings and strong R&D capabilities, exporting products to industrially advanced nations including Germany, Japan, and the USA.

Robotics & Automation Application: In the field of robotics and automation, TCB supplies precision components critical for structural simplification and operational reliability. Their low-noise deep groove ball bearings and precision angular contact ball bearings are essential for robotic joints and electric motors, ensuring smooth, quiet operation and accurate positioning. Additionally, TCB provides maintenance-free plain bearings and high-load cylindrical roller bearings, which are widely used in robotic linkages and heavy-duty automation equipment to reduce downtime and withstand significant mechanical stress.

△ TCB Precision Low-Noise Bearings

2. Luoyang Hongyuan Bearing Technology Co., Ltd. (HONB)

Website: www.honb.com

Founded in December 2005, Luoyang Hongyuan is dedicated to the domestic substitution of high-precision bearings. Since starting R&D on robot bearings in 2010, after 15 years of technical accumulation, it has formed 4 major categories, 12 series, and a total of 150 models providing joint solutions for robots. It achieved mass production of industrial robot bearings in 2012, exported to Japan in 2020, and achieved mass production of humanoid robot bearings in 2022, verifying international recognition of its technical strength. It currently occupies over 90% of the domestic robot bearing market.

△ Hongyuan Bearing Robot Bearing Schematic (Images: Harmonic Reducer Crossed Roller Bearing, RV Reducer Bearing, Planetary Reducer Bearing, Harmonic Reducer Flexible Bearing)

3. Jiangsu Nanfang Precision Co., Ltd. (002553)

Website: www.nf-precision.com

As the first listed company in the needle roller bearing industry, Nanfang Precision mainly develops and produces various needle roller bearings, ball screws, and one-way clutches. Its products are applied in RV reducers, planetary reducers, and cycloidal pinwheel reducers for industrial and humanoid robots, as well as robot linear drive joints.

△ Nanfang Precision Needle Roller Bearing Products

4. Zhejiang XCC Group Co., Ltd. (603667.SH)

Website: www.xcc-zxz.com

Founded in 1999, Zhejiang XCC Group mainly produces bearings, precision mechanical parts, and parts for automotive safety and thermal management systems. In the field of humanoid robots, relevant products include lead screws and bearings.

It is reported that XCC has successfully developed a full series of robot bearing products, supplying robot reducer manufacturers such as NGC (Nanjing High Speed Gear), Newstart, Leader Harmonious Drive, Jiya Machinery, and Laifual Drive.

△ Robot Harmonic Reducer Bearing

5. Zhejiang Changsheng Sliding Bearing Co., Ltd. (300718)

Website: www.csb.com.cn

Changsheng Bearing’s research direction in the robot component field is mainly self-lubricating bearings applied at joints, products in some linear actuators, and related components for dexterous hands. The sliding bearings developed have the characteristics of low cost, high strength, high load, and maintenance-free operation, which can effectively simplify mechanical design and structure, reduce costs, and extend service life.

Currently, Changsheng Bearing’s cooperation with domestic robot customers is proceeding in an orderly manner, and self-lubricating bearings for robot joints and spherical plain bearing products have achieved small-batch production and sales.

6. Luoyang Xinkai Bearing Technology Co., Ltd.

Website: www.xkzc.net

Founded in 2002, Luoyang Xinkai is dedicated to the R&D and manufacturing of non-standard, high-precision, and high-strength special bearings. Main products include shield machine bearings, ultra-thin wall stainless steel bearings, precision screw units, crossed roller bearings, precision turntable bearings, and special bearings for robot reducers, with precision reaching P2 grade; processing size range is Φ20-Φ2000mm. Applications include shield machines, high-precision CNC turntables, CNC vertical lathes, machine tool spindles, screw units, military industry, direct drive motors, industrial robots, spiral pipe welding machines, etc.

△ Xinkai Bearing Related Products

7. Ningbo Mairui Machinery Co., Ltd.

Website: www.nbmairui.com

Founded in 2014, Ningbo Mairui has been deeply cultivated in the field of bearing (and assembly) R&D and manufacturing. It has formed a full product line including deep groove ball bearings, non-standard bearings, elevator door pulleys, step chain wheels, door locks, door vanes, motors, and reducer accessories.

△ Mairui Machinery Bearing Products

8. Ningbo Shilong Bearing Co., Ltd. (RCL)

Dedicated to high-precision robot bearings. For example, harmonic reducer bearings, with characteristics like high reduction ratios, high torque density, and zero backlash, are widely used in high-demand fields such as industrial robots, service robots, aerospace, medical equipment, and semiconductor manufacturing.

△ Shilong Harmonic Reducer Bearings

9. Shanghai SXD Precision Bearing Manufacturing Co., Ltd.

Website: www.sxdbearings.com

Shanghai SXD specializes in producing high-precision, low-noise, long-life special miniature precision bearings. It mainly produces metric/imperial size bearings with bore diameters of (1-20) mm, widely used in various miniature motors, instruments and meters, precision instruments, home appliances, fishing gear, and other fields.

△ SXD Bearing Products

10. Zhejiang Zhaofeng Mechanical and Electronic Co., Ltd. (Zhaofeng Shares: 300695)

Website: www.hzfb.com

Zhaofeng is a leading enterprise in China’s automotive hub bearing industry. In bearing manufacturing, its high-precision and high-reliability products can meet the rigorous requirements of robot joints under complex motion, effectively improving robot stability and lifespan. To provide high-precision transmission components for humanoid robots, it established a wholly-owned subsidiary, Zhaofeng (Hangzhou) Intelligent Equipment Co., Ltd., aimed at developing, manufacturing, and selling ball screws, planetary roller screws, and bearing unit products. Relevant product R&D and trial production are underway.

11. Haining Qisheng Bearing Co., Ltd. (QSZ)

Website: www.qs-bearing.com

Haining Qisheng Precision Bearing Co., Ltd. (QSZ) specializes in R&D and production of precision angular contact ball bearings and matched precision angular contact ball bearings, with product precision reaching P5 and P4 grades.

In the field of humanoid robots, after 2 years of strict material testing, structural optimization, and life verification, Qisheng Precision successfully developed special bearings for humanoid robot joints, meeting the requirements of “extreme thinness + ultra-high flexibility + long life.” Currently, the products have achieved small-batch mass production, providing core support for the precision movement of robot joints.

△ Qisheng Precision Bearing Products

12. Suzhou Tiejin Electromechanical Technology Co., Ltd. (STT)

Website: www.stt-bearing.com

Founded in 2012, Suzhou Tiejin focuses on the manufacturing and R&D of special miniature bearings and bearing equipment. Products are widely used in drones, automobiles, home appliances, medical devices, and many other fields.

In the emerging market of humanoid robots, dexterous hands are the main development direction for Suzhou Tiejin. The current product matrix includes: 03/05 series miniature harmonic reducer flexible bearings, four-point contact bearings with an inner diameter of 1.5~6mm for bearing the axial force of miniature screws, linear actuator rod end fisheye bearings, and 1x3x1 deep groove ball bearings for hollow cup motors.

△ Suzhou Tiejin Dexterous Hand Special Miniature Bearings

13. Wanxiang Qianchao Co., Ltd. (000559)

Website: www.wxqc.com.cn

In the robotics field, including humanoid robots and industrial robots, Wanxiang Qianchao has laid out products such as roller screws and planetary roller screws. At the same time, it has established special teams for robot joint core precision shafts, precision crossed roller bearings, thin-wall tapered roller bearings, and ball bearings.

Among them, robot joint core precision shaft products have completed manual sample delivery and small-batch installation delivery; precision crossed roller bearings have established a project team and are conducting sample development and industrial investment planning centered on robot customers; thin-wall tapered roller bearings and ball bearings already have relevant products and are currently in project development with top robot customers.

14. Shandong Bote Bearing Co., Ltd.

Website: www.botbearings.cn

Founded in 2004, Shandong Bote specializes in the production of thin-wall special bearings. It developed a series of high-end industrial robot specialized precision bearings, maximizing the reliability of robot joint operation through structural design. It has achieved successful matching in robot RV reducers, harmonic reducers, and other joint parts, applied in key fields such as industrial robots, mechanical arms, and medical devices, successfully substituting imported products.

△ Shandong Bote Robot Bearings

15. Sinomach Precision Industry Group Co., Ltd.

Website: www.sinomach-pi.cn

Sinomach Precision mainly covers bearing business, abrasives business, and supply chain business. It possesses relevant technologies required for humanoid robots, as well as the development and production capabilities for a series of rolling bearings for robots.

16. Xinchang HNRH Bearing Co., Ltd.

Website: www.hnrhbearing.com

Founded in 2008, Xinchang HNRH specializes in producing tapered roller bearings, reducer bearings, robot RV reducer bearings, and small tapered bearings. In 2023, the company achieved mass production of large drone bearings, and in 2024, its product line expanded to diverse fields such as industrial robots, humanoid robots, and robot dogs.

△ HNRH Humanoid Robot Joint Crossed Roller Components

17. Suzhou Bearing Factory Co., Ltd. (SBF / 430418)

Website: www.sbfcn.com

Suzhou Bearing Factory (SBF) is a professional design and manufacturing company for needle roller bearings, cylindrical roller bearings, and needle rollers. Main product series include needle roller bearings, cylindrical roller bearings, thrust bearings, roller bearings, linear motion roller guide supports, rolling elements, and various customized non-standard component products.

18. Fujian Longxi Bearing (Group) Corp., Ltd.

Website: www.ls.com.cn

Longxi utilizes globally leading PTFE fabric liners, molded liners, and precision simulation extrusion “three key core technologies” to comprehensively lay out joint bearings in future industries such as humanoid robots and low-altitude economy applications. Currently, joint bearings for humanoid robots are in the development or small-batch sampling/testing stage. Relevant business product revenue is already 1.3 million yuan, and in March 2025, it was awarded the “Excellent Partner Award” by Zhiyuan Robotics (Agibot).

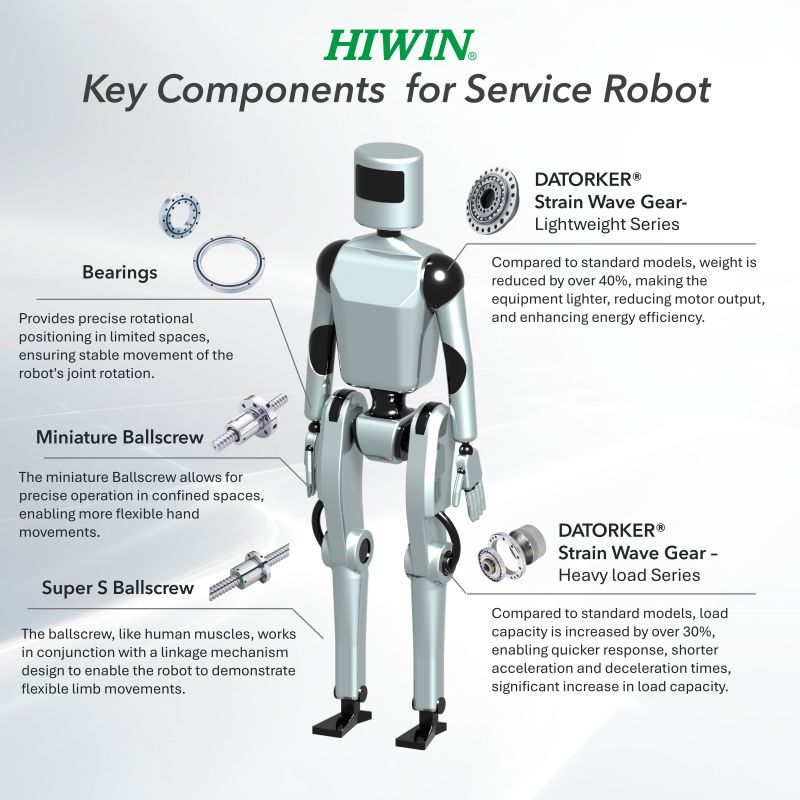

19. HIWIN (Taiwan)

Website: www.hiwin.tw

HIWIN provides key component solutions for humanoid robots, including precision ball screws, lightweight harmonic gear reducers, and ultra-thin crossed roller bearings, ensuring humanoid robots achieve extremely lightweight structures and precise, stable operation.

△ HIWIN Key Components for Service Robot

20. Shenzhen Daiwa Bearing Co., Ltd.

Website: www.dgbearing.com

Shenzhen Daiwa Bearing (DAW) was founded in 2002. It is a professional miniature bearing manufacturer, mainly producing and selling metric miniature bearings, imperial miniature bearings, flanged bearings, stainless steel bearings, and flat thrust ball bearings with an inner diameter of 1-15mm and an outer diameter under 30mm. Products are widely used in miniature motors, cooling fans, instruments, printers, copiers, precision instruments, mechanical equipment, precision machine tools, etc.

△ Daiwa Bearing DAW mr series deep groove ball bearings

21. Luoyang PRS Precision Bearing Co., Ltd.

Website: www.prszc.com

Luoyang PRS, founded in 2003, is dedicated to the development and production of non-standard, high-precision special bearings. Main products include precision crossed cylindrical roller bearings, precision crossed tapered roller bearings, thin section bearings, ZKLDF high-precision thrust angular contact ball bearings, precision angular contact ball bearings, and robot bearings. Precision can reach P4/P2 levels. Widely applicable to electronics, medical equipment, energy, machine tool equipment, testing equipment, robots, and industrial automation equipment.

△ Luoyang PRS XRU Series Robot/Harmonic Reducer Crossed Roller Bearing

Eight Major Multinational Bearing Suppliers

22. SKF (Sweden)

Website: www.skf.com/cn

SKF Group, founded in 1907 with headquarters in Gothenburg, Sweden, is one of the world’s largest manufacturers of rolling bearings. It mainly produces various bearings, seals, and special steels for bearings, accounting for 20% of global bearing production.

△ Reali-Slim Thin Section Bearings

23. Schaeffler Group (Germany)

Website: www.schaeffler.com/en

Drive technology company Schaeffler provides a wide range of key components for humanoid robots, including harmonic reducers, planetary reducers, ball screws, planetary roller screw assemblies, joint support bearings, relay sensors, etc.

Schaeffler’s innovative XZU double-row angular contact needle roller bearings designed for industrial robots have now introduced lightweight versions and more compact design versions for the humanoid robot market. Benefiting from improved friction performance and higher tilting rigidity, these bearings can control the movement of humanoid robot systems more efficiently and precisely, suitable for robot joints and harmonic reducers.

△ Schaeffler XZU double-row angular contact needle roller bearings combine compact design and high efficiency

24. Timken (USA)

Website: www.timken.com

Founded in 1895, The Timken Company is a global technology leader in engineered bearings and industrial transmission. Timken® engineered bearings feature precision tolerances, unique internal geometries, and high-quality materials. Products include tapered roller bearings, spherical roller bearings, cylindrical roller bearings, thrust bearings, ball bearings, spherical plain bearings, precision bearings, etc.

△ Crossed Roller Bearing (TXR) produced by Timken

25. NSK (Japan)

Website: www.nsk.com/eu-en

NSK Ltd., founded in 1916, was the first manufacturer in Japan to design and produce bearings. Its core bearing industry ranks first in Japan. NSK bearings have been used by global robot OEMs for over 20 years, possessing a wide product portfolio suitable for various robot applications: deep groove ball bearings, flanged ball bearings, angular contact ball bearings, needle roller bearings, spherical roller bearings, tapered roller bearings, etc., as well as new wave bearings for harmonic gears used in industrial, collaborative, service, and warehouse robots.

△ NSK Bearings

26. NTN (Japan)

Website: www.ntn-snr.com

NTN, founded in 1918, is a precision machinery manufacturing company that develops, produces, and sells bearings and constant velocity joints. Its main product—bearings—are important precision parts supporting machine operation, widely used in automobiles, wind power, railway vehicles, robots, and other fields. It is reported that NTN is a bearing supplier for Tesla humanoid robots.

△ NTN Reducer Bearings

27. JTEKT (Japan)

Website: www.jtekt.co.jp/c/

JTEKT Corporation was established in 2006 through the merger of Koyo Seiko (founded in 1921) and Toyoda Machine Works (founded in 1941). Its main businesses are the production and sales of automotive steering and drive components, bearings and oil seals, and machine tools.

△ JTEKT (Koyo) Angular Contact Ball Bearings

28. MinebeaMitsumi (Japan)

Website: www.minebeamitsumi.com

MinebeaMitsumi is a global comprehensive precision component supplier. Starting from ultra-precision machining technology represented by bearing manufacturing, it spans fields such as motors, sensors, semiconductors, and wireless transmission to provide customers with excellent products and services.

In the humanoid robot field, MinebeaMitsumi’s solutions cover full-link requirements such as robot joint control, dynamic sensing, and efficient drive. Related products include thin bearings, ball bearings, frameless motors, six-axis force sensors, torque sensors, stepper motors, electric grippers, cooling fans, high-speed transmission connectors, etc.

△ MinebeaMitsumi Humanoid Robot Solutions

29. NACHI-Fujikoshi (Japan)

Website: www.nachi.com.cn

NACHI-Fujikoshi Corp. operates under the philosophy of “contributing to the development of manufacturing.” It has three major machinery manufacturing businesses: mechanical tools, functional components, and materials. After 75 years of development, it continuously combines various core technologies for R&D. Currently, the company’s main products include cutting tools, machine tools, bearings, hydraulic equipment, robots for automated production, special steel, and machinery and environmental systems for the IT industry.

The above information is organized based on official company websites and online information. If there are any errors or omissions, please join the group to supplement!