Where Robotics, Hard Tech, and Entrepreneurship Redefine Learning

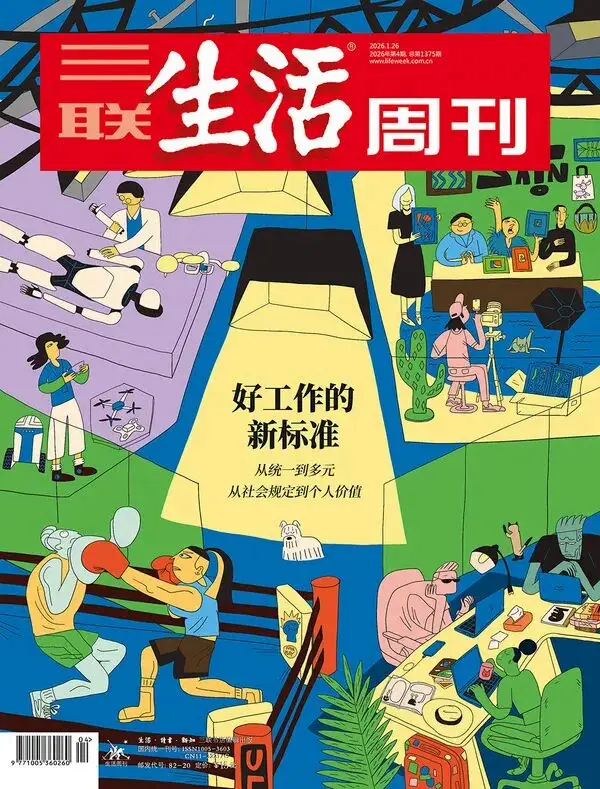

“As traditional standards of ‘good work’ waver, it becomes an opportunity to reexamine work within the context of human life and meaning—ultimately rediscovering its purpose.” —Lifeweek Magazine, Issue 4, 2026

By Zhang Congzhi | Photos by Cai Xiaochuan

Since its founding in 2014, the Songshan Lake XbotPark Robotics Base (hereafter “XbotPark”) in Dongguan, Guangdong, has incubated over 80 hard-tech startups with an 80% survival rate. Six have become industry “unicorns,” and several boast valuations exceeding ¥10 billion. While resembling a startup incubator, XbotPark also functions as a university, attracting student entrepreneurs who treat innovation as education—honing engineering and design thinking through product development. This hybrid model aims to erase boundaries between academia and industry.

From RoboMaster to XbotPark

Kuang Zheng, born in 1995, studied computer science and joined DJI Innovations (SZ:002168) as a sensor engineer in 2017. There, he worked on RoboMaster—a robotics competition where wheeled robots duel in simulated combat. Kuang’s task was to develop sensors detecting bullet impacts and damage severity. When his team sought flexible “e-skin” sensors for full-body coverage, they found no viable suppliers. The idea lingered, and in 2020, Kuang joined XbotPark after Professor Li Zexiang encouraged him to launch Moxian Tech.

Nestled beside Dongguan’s Songshan Lake, XbotPark’s 98-acre campus—opened in 2023—defies the city’s factory-dominated reputation with lush gardens, R&D labs, and even a kindergarten. “We’re not entirely sure what we are,” jokes Li, 64, a Hunan native who earned degrees from Carnegie Mellon and UC Berkeley before joining HKUST in 1992. Dubbed the “professor who understands startups,” Li mentored DJI’s founder Frank Wang and co-launched XbotPark in 2014 with HKUST colleagues Gao Bingqiang and Gan Jie to address China’s manufacturing limitations. “Without homegrown global brands,” Li notes, “entire industries stagnate in low-margin imitation.”

Startup Methodology: From 0 to 1

After entering XbotPark in 2020, Kuang first joined a six-week innovation bootcamp. During this period, mentors guided teams through the entire startup lifecycle—from product definition and design to prototyping, manufacturing, sales, operations, and management. “The bootcamp provided a quiet, secure environment where we could focus without feeling alone,” Kuang recalls.

Entrepreneurship involves many pitfalls, and everyone expects them. Li Zexiang shares his own early failures, including one that nearly bankrupted him: Birai, an LED wire-bonding machine company he co-founded with students. To secure investment, they signed share buyback agreements. Initially successful—customers arrived with bags of cash before products were even ready—the company collapsed when co-founders quarreled and abandoned the project. Li was forced to repurchase shares personally, ultimately shutting down the firm.

Tang Xiaoxi, XbotPark’s incubation lead of seven years, explains how the program has evolved. Beyond the main 4-6 week summer/winter bootcamps, XbotPark now offers monthly two-week mini-camps and regular workshops. Each cohort typically includes 50-60 participants—mostly university students, plus some social entrants with work or startup experience like Kuang. The diverse backgrounds often spark team formation during the program.

Post-bootcamp, teams enter a “pre-exploration” phase with unconditional ¥50,000 funding to refine product concepts and technical roadmaps. Next comes the “exploration” phase: if teams pass XbotPark’s review, they receive ¥500,000 in seed investment—equivalent to institutional angel funding. Kuang initially researched flexible pressure sensors, discovering that most manufacturers used coating-based approaches where two surface layers generate resistance changes upon contact. At the time, the largest market for such sensors was testing equipment—measuring tire treads or mattress comfort—where longevity mattered less and customization costs were lower.

But Kuang realized consumer applications demanded the opposite: longer lifespans, larger volumes, and cost sensitivity. His team pivoted, embedding the “coating effect” within materials themselves—a piezoresistive approach they use to this day.

Initially, Kuang’s team aimed to create smart carpets with embedded flexible pressure sensors for light interaction and home appliance connectivity—children could play games directly on the floor. But they quickly recognized this consumer direction was commercially unviable, shifting instead to B2B applications where more scenarios existed.

Li Zexiang consistently advises against B2B industries before age 35, citing numerous failures in agriculture where student teams struggled. Yet he also admits many current projects surprise him—like a dishwasher washing few dishes in five seconds. “As long as young people can articulate the logic behind their ideas, and that logic is sound, we’ll support them,” he says. In 2021, Kuang founded Moxian Technology (Dongguan) Co., Ltd., securing XbotPark’s first exploration-phase investment: ¥500,000 total.

The Benmo Tech Story: Pivoting to Success

Zhang Di, founder of Dongguan Benmo Technology Co., Ltd., is Kuang’s contemporary and another “unruly young person.” During graduate studies, Zhang suddenly envisioned removing the reducer—a key component in traditional electromechanical systems—and developed a new direct-drive motor technology improving system response speed and lifespan. He immediately recruited classmates to start a business.

Initially targeting industrial robots—a “chokepoint” sector for China with higher margins—Zhang discovered it was prohibitively difficult for startups. “It’s not just about technical breakthroughs,” he explains. “Consider: one minute of factory downtime costs how much? Their product import processes are lengthy, and they heavily prioritize supplier trust—which we lacked, having no successful cases.”

After this failure, in 2019, Zhang returned to Songshan Lake XbotPark and founded Benmo Tech. This time, abandoning industrial robots, they targeted emerging home robotics like floor washers and robotic vacuums. These smaller robots required more compact, durable direct-drive motors. Zhang’s products quickly found market traction, and business began rapid growth.

Among XbotPark’s startup teams, few find their path immediately. Tang Xiaoxi mentions one team that pivoted over 20 times, some having already built prototypes and received XbotPark investment, yet still changed direction. “People often ask if we’re running a ‘horse race’ mechanism,” she says. “Fundamentally, we don’t want everyone crowding one sector or creating competition. If one team is already doing something well, others should give them more time. But each team is independent—we don’t intervene in how they view opportunities in each field. If they insist on pursuing something, we have no problem.” Today, XbotPark’s startup directions span smart home, consumer electronics, sports health, pets, and environmental protection.

Leveraging Supply Chain Advantages

In 2021, Kuang’s team produced an A4-paper-sized sample where only a rubber-stamp-sized area functioned properly. This poor consistency made mass production an imperative challenge.

Initially, they sought contract manufacturing from polymer material factories, only to discover that three different factories produced different performance from identical designs. The team once considered giving up, but in the process recognized advantages in their technical approach: low cost, long lifespan, impact resistance, high temperature tolerance, and flexible bending. “Our biggest problem was finding factories to solve mass production processes, but we were too small. Looking around, we had to do it ourselves.”

In 2022, Moxian Tech secured new funding—several million yuan—and resolved to build their own production line. With just 15 people, they sought markets while constructing the line. Frequently visiting Huaqiangbei, they once passed the second floor of Huaqiang Electronics World, noticing many electronic pianos. Touching the keys, they found silicone construction with no dynamic pressure sensitivity or volume variation. Kuang asked shopkeepers how to produce different sounds. “Turn the knob beside it while playing, like a DJ,” they replied. Kuang felt this consumer experience was poor, befriended the owners, learned where these pianos were manufactured, and discovered their need for product improvement.

Moxian Tech’s first formal order came from an electronic piano manufacturer. “Factories need validation—how else do you know if your production works? The best validation is delivering products to customers. But we didn’t dare accept large orders initially; once quality control fails, reputation is gone,” Kuang explains. Huaqiangbei partnerships were ideal: “First, their quality requirements weren’t so strict, with higher tolerance. Second, they sold inexpensive products, so consumers didn’t have high after-sales expectations.”

Flexible sensors gradually opened markets. Later, cable manufacturers, medical device makers, automotive seat producers, and even adult toy companies became customers. Recently, with humanoid robots booming, Moxian Tech’s flexible sensors have been applied by renowned domestic and international companies to robotic dexterous hands for tactile feedback—their products becoming even more sought-after. Moxian Tech has now moved to a building outside XbotPark, with a simply furnished exhibition hall. There I met Kuang this year: 30 years old, tall and thin, oval-faced, casually dressed. He says Moxian Tech now has 30+ people, all young, and though business grows fast, they’re not rushing expansion.

Li Zexiang often calls the Greater Bay Area “Hollywood for manufacturing.” Recently, he hosted an MIT delegation of 50+ students and faculty. Several entrepreneurial students described their difficulties: working on metal 3D printing, they found establishing supply chains in the U.S. nearly impossible. One product required 100+ suppliers; missing one screw or nail meant failure. They even tried Eastern Europe without success, finally sourcing components from Shenzhen’s Huaqiangbei, shipping them back to the U.S. for assembly—but at prohibitive cost.

Li recognizes that even in Shenzhen and Dongguan, many supply chain resources cater to large corporations; small companies often must seek small manufacturers with questionable quality and pricing—pitfalls his startup teams have experienced. Zhang Di also realized: “When any new technology emerges, supply chains aren’t fully prepared. Sometimes you have to make dumplings just for the vinegar—without this, you can’t move forward.” Benmo Tech has raised considerable investment recently, but they’ve calculated that significant R&D expenses were wasted. “Many situations: some projects failed, some satisfied me and customers but couldn’t be produced. Some could be produced, but after a while mysterious problems emerged—you couldn’t locate the issue. By the time you did, no supplier could solve it or quoted astronomical prices.” Benmo Tech now has 400+ people, shipping 1.5 million direct-drive joint motors in 2024, mainly for home robots. They’ve also launched their own wheeled-leg robots “Xingtian” and “TITA.”

Supply chains have countless pitfalls, but this is also the moat for hard-tech entrepreneurship. Li Zexiang says: “Even if outside companies want to copy you, they must find these 100+ components and repeat all your mistakes. By then, if you iterate faster, you’ll outrun them.”

From “Hunting” to “Farming” Talent

XbotPark has birthed 80+ hard-tech startups, including six industry unicorns like Narwal, YD Tech, OneRobotics, and HAI Robotics. As a new wave of technology arrives, visitors nationwide come to learn XbotPark’s model. Li sees opportunity to transform China’s traditional engineering education.

Behind Li’s 1999 founding of Shenzhen Googol Tech lies a widely circulated story. Seeking industrial upgrading but lacking strong local universities, Shenzhen officials visited HKUST, knocking on professors’ doors one by one. Li and colleagues Gao Bingqiang and Wu Hong were recruited back to co-found Googol Tech, which listed in 2023. But after starting the company, Li sensed contradictions between traditional engineering education and entrepreneurship: “What you do in business, schools completely disregard—they look at your papers and project funding.”

At HKUST, Li attempted curriculum reforms. He founded the Automation Technology Research Center, launched robotics competition courses, and advocated project-based, interdisciplinary teaching. However, many HKUST students treated the university as a stepping stone—earning credits for U.S. graduate school, then Wall Street or Silicon Valley jobs. Li’s robotics competitions initially attracted few students; eventually, some with mediocre grades but passion for tinkering emerged, including DJI founder Frank Wang.

To organize robotics competitions, Li frequently brought students to Shenzhen. “At HKUST, you might iterate once a month; in Shenzhen, you could iterate once a weekend.” He clearly remembers university town surroundings in Shenzhen’s Xili offering small machining and mold factories. “We’d eat noodles with factory owners while discussing—how to process this part, how to make that component—and by the time we finished eating, the parts were ready.” Many students told Li they learned more in this course than in four years of university.

Li also participated in Southern University of Science and Technology’s founding and collaborated with Harbin Institute of Technology, Guangdong University of Technology, and other mainland institutions on educational reform programs—encountering various obstacles. “Traditional engineering education teaches problem analysis and solving, but not problem definition and discovery. So students don’t own the problem, won’t dig deep into it, publish a paper, graduate, and leave,” Li says. Having come through this system himself, over the years everyone discussed industry-university-research integration, encouraging teachers or students to start businesses, but with poor results. “We used to run relay races—each person runs a leg before handing off, constantly dropping the baton. That’s why universities have piles of achievements that never translate.”

In early XbotPark days, Li recruited nationwide, calling this model “hunting”—like traditional angel investing, searching worldwide for “prey,” investing when suitable projects appeared. But in recent years, Li believes “hunting” should shift to “farming”—creating more industrial innovation test fields, cultivating from seed to full growth cycle, requiring deeper educational reform participation.

Over recent years, Li and collaborators have launched innovation bases and colleges in Ningbo, Changzhou, Chongqing, Hong Kong, Shenzhen, Guangzhou, and elsewhere. The Shenzhen Institute of Technology, founded in 2021, is among them. Deputy Dean Yu Ying, responsible for daily operations, explains that over several years, 120,000 people applied, with 500+ entrepreneurs admitted forming 66 teams—half focused on AI + hardware. “When entering, people jokingly called themselves ‘three-nothings’—no ideas, no teams, no resources, including some high school graduates. But after two and a half years, 60% of teams achieved ¥30-50 million valuations.”

These new colleges and bases share XbotPark’s experience and resources while organizing student participation in various bootcamps. Li emphasizes that especially within schools, implementing new engineering education means bridging the education-industry gap, overturning entire curriculum structures, teaching methods, and evaluation systems. “We don’t want students who only score high on tests, but those with curiosity, willingness to act, and persistence,” Li says. Entrepreneurship and school learning are fundamentally different. “In traditional education, you succeed once, publish a paper or apply for a patent. But product development requires hundreds or thousands of iterations—sometimes just small changes, like appearance, but without this process, success is difficult.”

The new engineering education Li now advocates combines entrepreneurship with student learning, so graduates possess basic entrepreneurial capabilities—and this reflects in their academic performance. Li annually examines one metric post-graduation: student entrepreneurial density index. Their definition: graduates founding or co-founding companies with social investment and market recognition. Dividing these entrepreneurs by total graduates yields the entrepreneurial density index. Li explains that in traditional engineering education schools, MIT leads at approximately 1%, with Stanford second at 0.5%. Someone calculated that MIT graduate-founded companies’ combined revenue equals the world’s tenth-largest economy—exceeding South Korea’s GDP.

After extensive young entrepreneur exposure, Tang Xiaoxi observes shifting attitudes toward entrepreneurship over time. “For example, during the pandemic years, entrepreneurial confidence suffered greatly; many university students preferred ‘civil service exams.’ Recruiting students was also difficult then.” She tells me that in the past year or two, situations have clearly improved, and societal attitudes toward young people have changed significantly—more willing to listen to their voices. She also discovered: “Previously many students aimed for big tech companies, like a tradition—seniors entered big tech, so they must too. But now, many hold more open attitudes toward joining small factories, especially startups.”